by marketing | Sep 14, 2023

SALINAS, CA. (September 5th, 2023) – Stout Industrial Technology, a leading pioneer in agricultural technology, is excited to announce its participation at this year’s prestigious International Forum for Agricultural Robotics (FIRA USA). The event will take place from September 19-21, 2023, at the Salinas Sports Complex in Salinas, CA, and will bring together industry leaders, experts, and enthusiasts in the field of agricultural robotics.

As a company that is revolutionizing the agricultural industry through cutting-edge AI technology and automation solutions, Stout Industrial Technology is thrilled to showcase its latest advancements and to foster connections with prospective customers and industry professionals at FIRA USA. The event provides an excellent platform for the company to demonstrate how its innovative technology is shaping the future of agriculture.

Attendees will have a variety of opportunities to engage with the Stout team and see the Smart Cultivator, an automated AI-powered weeder and cultivator, in action. The Stout team will partake in an Inno’Pitch session on September 20th, at 4:00 p.m. During this session, attendees can expect a 15-minute presentation followed by a dedicated and interactive Q&A session with the Stout team.

There will be two demonstrations where the Stout Smart Cultivator will operate in a romaine field for attendees to watch the machine in action. The demonstrations are scheduled for September 20th, at 10:15 a.m. and again on September 21st, at 2:00 p.m. Throughout the demonstration, attendees will have the opportunity to interact with Stout’s state-of-the-art Smart Cultivator. The Stout Industrial Technology team will be on-site, providing valuable insights and explanations about the machine’s capabilities, highlighting the company’s commitment to improving efficiency, productivity, and sustainability in critical labor heavy farming practices such as weeding and cultivating.

Ryan Mazzuca, Director of Business Development

“We are thrilled to be a part of this year’s FIRA USA and to showcase our Smart Cultivator machine that leverages our proprietary True Vision™ AI technology,” said Ryan Mazzuca, Director of Business Development at Stout Industrial Technology. “This event presents a unique opportunity for us and innovative growers alike to connect with industry leaders, exchange insights, and explore partnerships that will drive the future of agriculture.”

FIRA USA is widely recognized as a premier event for autonomous and robotic farming solutions, with a comprehensive program featuring expert speakers, panel discussions, and networking opportunities. Attendees stand to will gain valuable insights into the latest trends, challenges, and opportunities in the field, as well as witness live demonstrations of cutting-edge technologies.

Stout Industrial Technology invites all attendees to visit their booth #53 to learn more about the transformative technology of their Smart Cultivator and discover how it can minimize labor costs and increase farming efficiencies.

by marketing | Aug 4, 2023

Stout Industrial Technology Appoints New Leadership

SALINAS, CA (August 3rd, 2023)

Stout Industrial Technology, a prominent AI company focused on agtech solutions, is proud to announce two significant additions to its leadership team. Ryan Mazzuca joins as the new Business Development Director, and Lance Portman takes the helm as CEO. These strategic appointments are geared towards reinforcing Stout’s commitment to continued growth and enhancing its position as an industry leader in artificial intelligence and agricultural technology.

“I am looking forward to leading the innovative team at Stout,” said Portman. “Together, we will build upon Stout’s already impressive accomplishments and drive the company’s growth to even greater heights. Stout’s commitment to revolutionizing agriculture and supporting farmers is unwavering, and I am excited to be a part of this transformative journey.”

“I am looking forward to leading the innovative team at Stout,” said Portman. “Together, we will build upon Stout’s already impressive accomplishments and drive the company’s growth to even greater heights. Stout’s commitment to revolutionizing agriculture and supporting farmers is unwavering, and I am excited to be a part of this transformative journey.”

Portman brings a distinguished leadership background and record of successfully bringing products to market, stewarding innovative teams and constructing sound business practices, having held key executive roles at prominent companies across the globe, including BJ Services Company, Baker Hughes Incorporated, and PlantTape, a fully automated agriculture transplanting system. His extensive experience in managing diverse operations, specifically in the agricultural sector, will be invaluable in driving Stout’s mission to provide growers with durable, labor-saving farm solutions.

Mazzuca joins Stout as the new Business Development Director, bringing a wealth of experience from companies such as Bloomfield Robotics, Iron Ox, and Tanimura & Antle. His proven track record in identifying and cultivating strategic partnerships will play a pivotal role in expanding Stout’s market reach and solidifying its position in the industry.

“I am deeply honored to be a part of the talented, visionary team at Stout,” remarked Mazzuca. “Stout has already established an exceptional product that is positioned to shape the future of agriculture. I am looking forward to contributing to the team and supporting growers tackling the adoption of Stout’s cutting-edge technology.”

“I am deeply honored to be a part of the talented, visionary team at Stout,” remarked Mazzuca. “Stout has already established an exceptional product that is positioned to shape the future of agriculture. I am looking forward to contributing to the team and supporting growers tackling the adoption of Stout’s cutting-edge technology.”

With a steadfast commitment to agricultural innovation and a focus on developing AI solutions that empower growers, the Stout team continues to lead the charge in shaping the future of farming. The recent additions to the team are expected to contribute significantly to their ongoing success, further solidifying Stout’s position as the leader for AI solutions in the agriculture industry.

by marketing | Dec 9, 2022

Stout Industrial Technology Adds Global Distribution And Investment From CNH Industrial

Helping growers automate labor-intensive field work with artificial intelligence

SALINAS, CA (December 9, 2022)

Stout Industrial Technology, Inc. (Stout) has announced an investment from and global distribution agreement with CNH Industrial that will see Stout’s AI-powered Smart Cultivators sold and serviced at New Holland dealerships worldwide.

The machines simultaneously cultivate and remove weeds at the rate of 1 – 2 acres per hour and are anticipated to be available for sale at selected New Holland dealers in early 2023. Stout currently has Smart Cultivators operating in locations across the US and in the United Kingdom.

The minority investment by CNH Industrial adds Michele Lombardi to Stout’s Board of Directors and adds Stout’s proprietary vision system, neural network and AI expertise to CNH Industrial’s See & Act portfolio of products.

Stout Industrial Technology is a Salinas, CA based artificial intelligence company focusing on labor-intensive applications in agriculture. The Company builds software-defined implements for tractors that use machine vision and AI to identify and remove weeds via mechanical actuation instead of chemicals. Born inside a grower-shipper operation, Stout’s hardware and software solutions are developed from the grower’s perspective, hardened in the field prior to commercialization and continuously improved to help growers lower their operating costs and increase their margins.

Learn more at www.stout.ai or follow Stout Industrial Technology on LinkedIn.

CNH Industrial (NYSE: CNHI / MI: CNHI) is a world-class equipment and services company. Driven by its purpose of Breaking New Ground, which centers on Innovation, Sustainability and Productivity, the Company provides the strategic direction, R&D capabilities, and investments that enable the success of its global and regional Brands. Globally, Case IH and New Holland Agriculture supply 360° agriculture applications from machines to implements and the digital technologies that enhance them.

Across a history spanning over two centuries, CNH Industrial has always been a pioneer in its sectors and continues to passionately innovate and drive customer efficiency and success. As a truly global company, CNH Industrial’s 37,000+ employees form part of a diverse and inclusive workplace, focused on empowering customers to grow, and build, a better world.

For more information and the latest financial and sustainability reports visit: cnhindustrial.com

For news from CNH Industrial and its Brands visit: media.cnhindustrial.com

by marketing | Feb 25, 2021

Not too long ago, the idea of a machine cultivator that could tell the difference between the weeds and the crop would have seemed impossible. However, now it’s not only possible — it’s available. An innovative new automated machine developed by Stout Industrial Technology, the Smart Cultivator, can now eliminate weeds and cultivate ground in a single pass – with just one tractor and driver. With the critical labor shortages in the agriculture industry, it comes not a moment too soon.

The Smart Cultivator uses a cutting-edge artificial intelligence vision system, called Stout True Vision, to differentiate between the crop and weeds. A significant benefit Stout True Vision has over traditional machine vision is it automatically adjusts for lighting conditions, soil color, and plant sizes. To train it to recognize a crop — romaine lettuce, broccoli or iceberg, for example, thousands of images were labeled and uploaded so the machine could “learn” dozens of characteristics such as the color, leaf edges and shape and crown structure. Armed with that knowledge in the field, Smart Cultivator looks specifically for the commodity being grown and knows anything else should not be there.

The blades open and close around the plants and remove any weeds sur-rounding them as it moves down the rows. The cultivating and weeding blades, along with the row width and height, are all easily adjustable. The Smart Cultivator processes fields at one to two acres per hour.

“With the ability to reduce both labor needs and chemical inputs at the same time, early adopters of the Smart Cultivator have found that there is an immediate financial benefit,” says Steven Snyder, Chief Technologist at Stout Industrial Technology. “It’s a great fit for both organic and conventional growers.”

A Machine That Keeps Learning

Currently, Smart Cultivator has the ability to work in fields of leafy greens such as romaine, iceberg and red-leaf lettuce, and brassicas. New crops are continually being added, Snyder says. Tomatoes and melons are coming soon.

“If a grower contacts us about a specific crop, we have a system in place that allows us to very quickly get the images we need to train our system to work on a new commodity,” he says.

Rugged Construction Designed for Field Conditions

The Smart Cultivator has cutting-edge technology, but it is designed with the user in mind. It has a user-friendly, touch-screen interface, precision seed line tracking for tight machine-to-plant spacing, automatic blade depth control and more. The Smart Cultivator requires only a 1,000 RPM PTO and three-point hitch, with no electrical or hydraulic connection to the tractor needed.

It is also designed with field conditions in mind, Snyder says. The Smart Cultivator works on any soil type and has automatic bed pressure and height control systems, which adapt to different soils – even rocky ones.

“We wanted something that would be easy to use and extremely durable, because we know it’s really hard for businesses to integrate new technologies into their operations,” Snyder says. “It’s made of heavy steel, with shock absorbers, and all the electronics and wiring are completely sealed and waterproof. You can pressure wash it; it doesn’t need special handling. Growers who are already using it say it’s reliable, it works, and it’s easy to use,” Snyder says.

by marketing | Feb 15, 2021

Stout Industrial Technology Launches the Smart Cultivator

SALINAS, CA. (February 15, 2021)

After completing more than 1000 hours of trouble-free operation on their first prototype, Stout Industrial Technology completed the first commercial Smart Cultivator in May 2020 and now has completed its 16th commercial machine with more in production. With the initial commercial sales deliveries now completed and operating with success, Stout Industrial Technology is pleased to announce the availability of the Smart Cultivator to farming communities across the United States.

The Smart Cultivator is an automated weeder and cultivator that combines a proprietary, agriculturally proven mechanical platform with a cutting-edge artificial intelligence vision system, called Stout True Vision, to eliminate weeds and cultivate ground in a single pass. The machine processes fields at 1-2 acres per hour with one tractor driver and is rugged and durable. The machine features a self-tuning AI vision system, user-friendly touch screen interface, precision seed line tracking for tight machine to plant spacing, automatic blade depth control and more. The Smart Cultivator requires only a 1000 RPM PTO and 3 point hitch, with no electrical or hydraulics connection to the tractor. All electrical components are shockproof and waterproof.

“The Smart Cultivator addresses a critical labor shortage in the agriculture industry while simultaneously improving efficiencies in farming operations,” says Steven Snyder, Chief Technologist at Stout Industrial Technology. “Early adopters of the Smart Cultivator have found that there is an immediate financial benefit with the reduction in labor needs and the ability to reduce chemical inputs, making the Smart Cultivator a great fit for both organic and conventional growers.”

The Smart Cultivator is the first of many industrial technologies to come from the diverse group of innovators behind the Stout Industrial Technology brand. Combining a spirit of innovation and a background in product development, the team’s collective experience portfolio spans from space telescopes and virtual reality headsets, to automated farm equipment and high throughput specialty manufacturing lines.

Stout Industrial Technology looks forward to a bright future creating high quality, intelligent technology and machines that are designed to be dependable and last a lifetime.

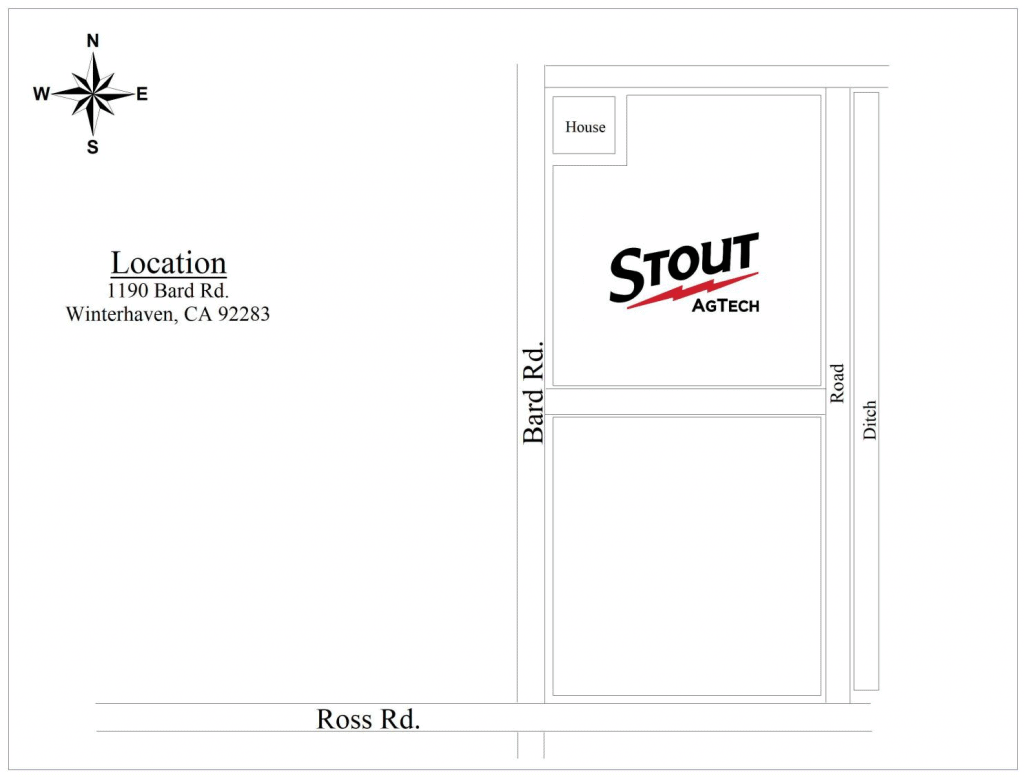

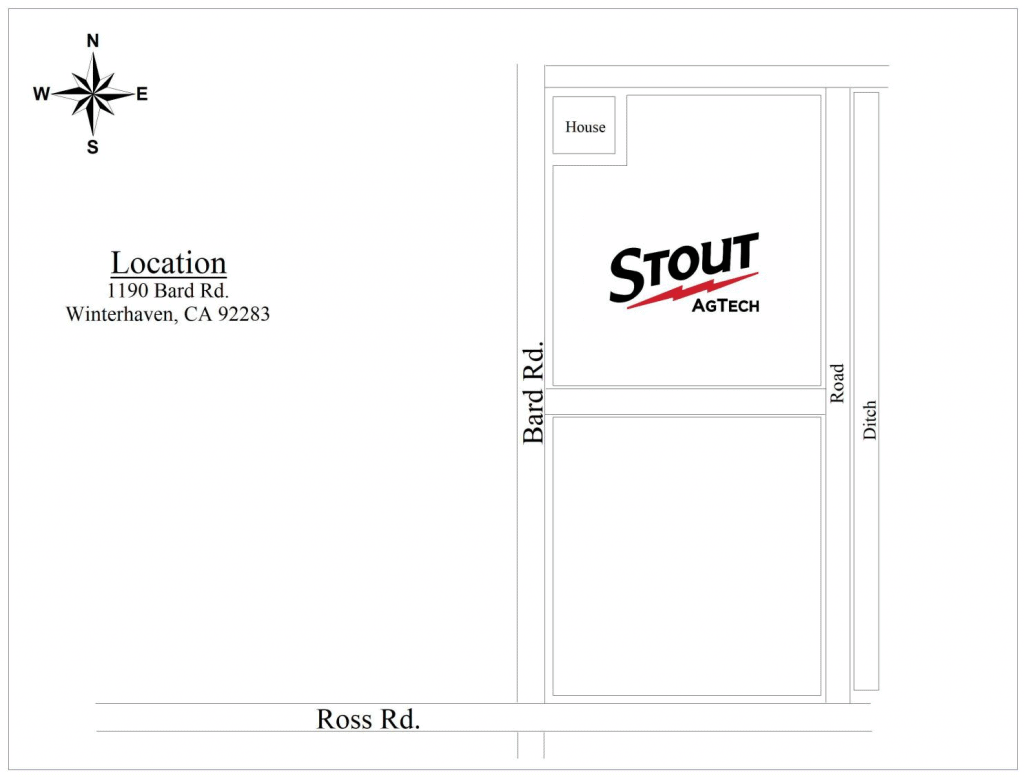

by stoutadmin | Nov 11, 2020

NOV 17-18, 2020 – YUMA, AZ

Come see the most technologically advanced agriculture machine on the market

Stout builds high-quality, intelligent agricultural machines designed to be dependable and last a lifetime.

We will be doing demos to show off it’s amazing capabilities and to answer any questions you may have about how it will fit into your specific farming practice.

“I am looking forward to leading the innovative team at Stout,” said Portman. “Together, we will build upon Stout’s already impressive accomplishments and drive the company’s growth to even greater heights. Stout’s commitment to revolutionizing agriculture and supporting farmers is unwavering, and I am excited to be a part of this transformative journey.”

“I am looking forward to leading the innovative team at Stout,” said Portman. “Together, we will build upon Stout’s already impressive accomplishments and drive the company’s growth to even greater heights. Stout’s commitment to revolutionizing agriculture and supporting farmers is unwavering, and I am excited to be a part of this transformative journey.”