Stout Surpasses 60,000 Acres and 3 Billion Plants Scanned

In a space crowded with prototypes and pilot programs, Stout Industrial Technology stands apart — delivering automation that’s working, scaling, and trusted in commercial fields around the world. The company announced today that its AI-powered Smart Cultivator has now covered more than 60,000 acres, scanned over 3 billion plants, and traveled the equivalent of three laps around the planet. These are real-world numbers from production farms across six countries—proof that Stout’s technology is scalable and built to perform.

With Smart Cultivators now operating across three continents, multiple countries, and numerous U.S. states, Stout’s system is getting smarter every day – adapting to a wide range of climates, growing regions and crops. Whether it is lettuce in Salinas, peppers in Virginia, or specialty crops in Europe, growers rely on Stout’s field automation to supplement labor with smart, per-plant precision in both weeding and cultivation. There’s no question: Stout has earned its place in mainstream agricultural operations.

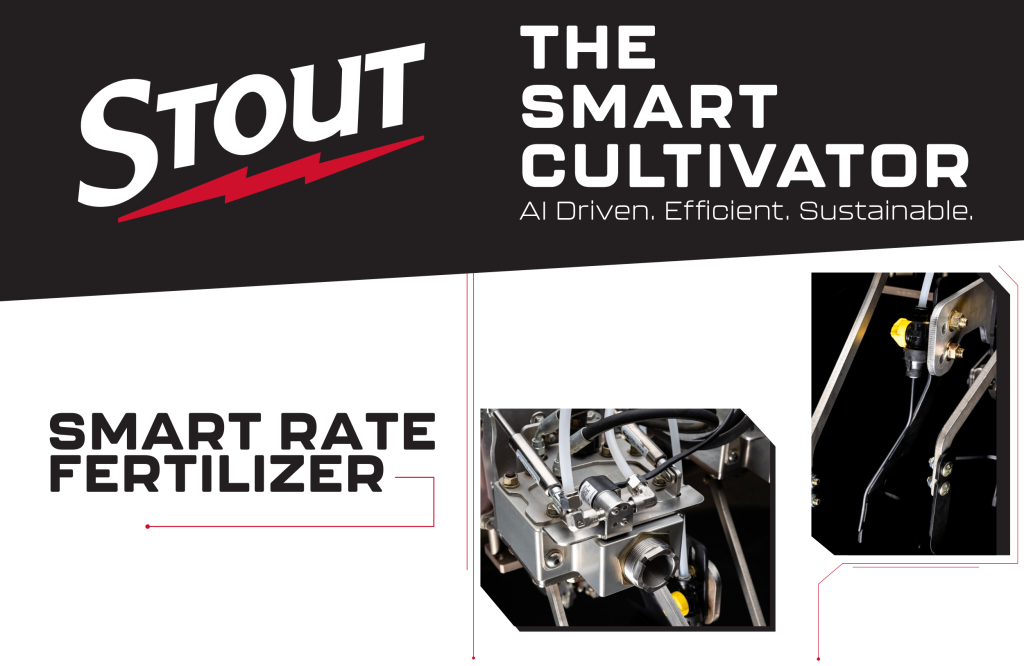

From design to deployment, every Stout machine is engineered for durability, ease of use, and clear return on investment. No special engineering team is required – Stout machines are built to be operated by existing tractor drivers with minimal training. Onboard computing means there’s no downtime due to connectivity issues, and when internet is restored, machines automatically update with the latest plant and weed models while syncing precise data to the Stout Data Dashboard.

This level of precision comes to life through the Stout Data Dashboard, which delivers real-time, per-plant insights across the field. From plant counts and growth rates to other health metrics, growers and executives gain a clear, actionable view of performance at a granular level. This visibility empowers teams to optimize operations, pinpoint field visits, and drive strategic improvements backed by high quality data.

Ryan Mazzuca, Director of Business Development

“What excites our customers most is the ability to finally see what’s happening at the field level—across every scanned acre,” said Ryan Mazzuca, Director of Business Development at Stout. “With our dashboard, growers aren’t just reacting to problems, they’re making faster, smarter decisions backed by real-time data.”

Stout’s rapid growth is no accident. The company’s machines were built in close collaboration with growers who understand the real challenges of farm operations. With a learn-by-doing mindset, product acceleration happens in the field – not in an office. Based in the heart of the Salad Bowl of America, Stout’s headquarters were intentionally established in the middle of active farmland, just minutes from its production and R&D facilities. This proximity allows the development team to engage directly with crops in real time, ensuring the technology is field tested, grower informed and ready for commercial operations.

Lance Portman, President

“Growers are tired of empty promises, and they want machines that work,” said Lance Portman, President of Stout. “At Stout, we’re no longer asking executives to take a leap of faith on our data analytics. We are showing you the acres, the numbers, the impact. This is automation that’s working to address multiple pain points for growers today — and it’s only getting better.”

About Stout Industrial Technology: Founded in 2019, Stout Industrial Technology, Inc. builds machines that reduce labor requirements for growers by combining AI with professional-grade industrial automation. Comprising team members from the high-stakes, high-performance industries of automotive racing, defense, aerospace, medical, agriculture, and manufacturing, Stout Industrial Technology provides solutions that are field-tested, environmentally friendly and help growers lower their operating costs while improving quality and yield.

“I am looking forward to leading the innovative team at Stout,” said Portman. “Together, we will build upon Stout’s already impressive accomplishments and drive the company’s growth to even greater heights. Stout’s commitment to revolutionizing agriculture and supporting farmers is unwavering, and I am excited to be a part of this transformative journey.”

“I am looking forward to leading the innovative team at Stout,” said Portman. “Together, we will build upon Stout’s already impressive accomplishments and drive the company’s growth to even greater heights. Stout’s commitment to revolutionizing agriculture and supporting farmers is unwavering, and I am excited to be a part of this transformative journey.”